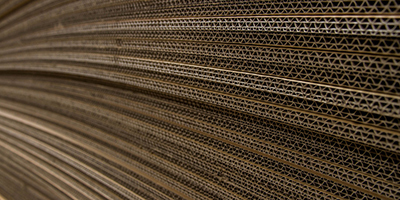

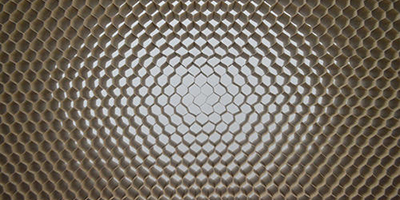

The honeycomb carton sandwich structure has a greater strength-to-mass ratio

The manufacturing process of honeycomb carton is dry and wet. In foreign countries, emulsified wax is used as a waterproofing additive in any manufacturing method. Although the wood pulp industry also uses paraffin as a carton waterproofing additive, most of them add it to the ingredients in the form of solid paraffin or molten paraffin, that is, directly added to molten paraffin or after adding paraffin. The crushed wood pulp is incompatible. Good products are of poor quality.

In manufacturing, the characteristics of using emulsified wax instead of solid paraffin are mainly reflected in two points: one is used as a water repellent for solid water paraffin, the amount of wood pulp is 1.2-2.0; /dry fiber) in order to achieve the same waterproof requirements. Secondly, the quality of cartons has been significantly improved. Due to the small average particle size of emulsified wax (less than 2 microns) and good fluidity, the wax can be evenly distributed in the carton with fine particles. The characteristic of emulsified wax itself can be that the wax particles are well absorbed by the carton to reduce wax loss.

The waterproof treatment of honeycomb carton has been used for a long time. The honeycomb carton is manually coated with a waterproof layer, which is bright, strong, waterproof, and will not collapse after painting. This kind of waterproofing agent is usually solvent-based (or oily), which is harmful to the operator's body, pollutes the environment, and is also harmful to the recycling of cartons. It is rarely used in recent years. Replace water or emulsion type waterproof coating.

The main features of honeycomb carton:

(1) Light weight, low material consumption and low cost. Compared with various other sheet structures, the honeycomb sandwich structure has a greater strength-to-mass ratio, so the finished product is cost-effective, which is the key to the success of honeycomb paper.

(2) High strength, smooth surface, not easy to deform. The honeycomb sandwich structure is approximately isotropic, and the structure is stable and not easily deformed. Its pressure resistance and bending resistance are required characteristics of box packaging materials.

(3) Good impact resistance and cushioning. Honeycomb paper is made of soft paper core and paper, which has good toughness and elasticity. The unique honeycomb sandwich structure can provide cushioning performance in all cushioning materials and improve energy absorption per unit volume. High-thickness honeycomb paper can replace the widely used EPS plastic foam pad.

(4) Sound absorption and heat insulation. The interior of the honeycomb sandwich structure is a closed chamber filled with air, so it has a good sound insulation effect.

(5) In line with modern environmental protection trends. Honeycomb paper is made entirely of recyclable paper, which can be recycled for 100% after use. The waste and corners of the corrugated box production process can also be molded and glued to form honeycomb corrugated paper mats of various shapes. Even if they are discarded, they can be naturally degraded and absorbed. Good green packaging materials