Honeycomb paperboard can be flame retardant isolation principle and main characteristics

The main raw materials of honeycomb paperboard are paper and adhesives, both of which are flammable materials. However, the honeycomb paperboard can be flame-retardant: the principle of isolation: when the flame-retardant honeycomb paperboard is in contact with the flame, the flame retardant can form a fluffy porous glass structure or carbon layer on the surface of the material to prevent heat transfer. Reduce the release of combustible gas and oxygen. For example, borides can be converted into molten boron oxide at high temperatures and form a glassy barrier layer on the surface of the material, thereby effectively preventing flame retardancy. Heat absorption principle: when heating the flame retardant material of honeycomb cardboard, the flame retardant will endothermic and decompose. Reaction, evaporation heat and thermal decomposition of flame retardants cause heat of vaporization of non-combustible volatiles, so the temperature of honeycomb paperboard is difficult to increase under heating conditions to prevent thermal degradation and play a role. Flame retardant effect. For example, inorganic flame retardants such as hydroxide and hydrated zinc borate decompose when heated, generating large amounts of water vapor, and discharging heat energy into the combustion system.

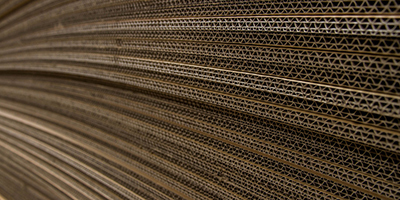

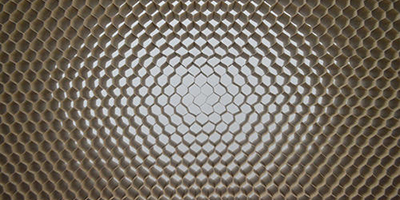

Honeycomb paperboard is made according to the principle of natural honeycomb structure. It is made by corrugating corrugated paper into countless hollow three-dimensional regular hexagons, thus forming a complete stress member, paper core and bonding surfaces on both sides. A new type of sandwich structure paper-based environmental protection and energy-saving material. The main features of honeycomb paperboard:

(1) Light weight, low material consumption and low cost. Compared with various other sheet structures, the honeycomb sandwich structure has a large strength/mass ratio, so the performance/price ratio of the finished product is good, which is the key to the success of honeycomb paperboard.

(2) High strength, smooth surface, not easy to deform. The honeycomb sandwich structure is roughly isotropic, the structure is stable, and it is not easy to deform. Its excellent pressure resistance and bending resistance are important characteristics required for box packaging materials.

(3) Good impact resistance and cushioning. Honeycomb paper is made of flexible paper core and paper, which has good toughness and resilience. The unique honeycomb sandwich structure has excellent cushioning performance and higher energy absorption rate per unit volume among all cushioning materials. High-thickness honeycomb paperboard can replace the widely used EPS plastic foam pad.

(4) Sound absorption and heat insulation. The interior of the honeycomb sandwich structure is a closed chamber filled with air, so it has good sound insulation performance.

(5) No pollution, in line with modern environmental protection trends. The honeycomb paperboard is made entirely of recycled paper and can be recycled and reused 100% after use. The waste and corners of the corrugated box production process can also be molded and glued to form honeycomb corrugated cardboard mats in various shapes. Even if they are discarded, they can be naturally degraded and absorbed. Good green packaging materials.