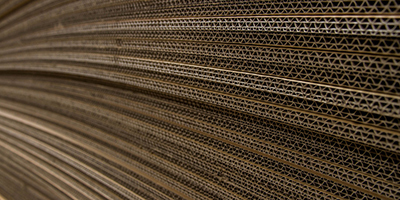

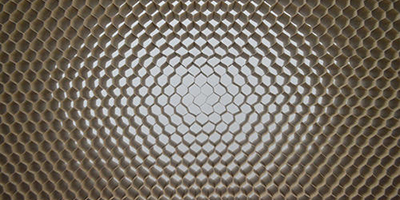

1. Low materials and light weight: the paper used per square meter to make 6mm thick honeycomb paperboard with side 4 or side 6 is 3.6-4.3 square meters, and the same thick corrugated box board (5 layers of AB tiles) per square meter The consumption of rice is 6 square meters, and the material of honeycomb paperboard is 30-40% less than that of corrugated paperboard.

2. High compressive and flexural strength: The frontal compressive strength of 6mm thick honeycomb paperboard is 5-10 times that of ordinary corrugated paper, and the flexural strength of ordinary honeycomb paperboard is 5-30 times that of corrugated paper (refer to national industry standard data).

3. No directional restriction: Compared with corrugated paper, the application of honeycomb paperboard has no directionality, and honeycomb paperboard has strong bending resistance in any direction.

4. Good moisture-proof performance and not easy to deform: Honeycomb paperboard can effectively prevent moisture from penetrating from the outside to the inside due to its completely sealed structure; while the corrugated paper is transparent from top to bottom, and moisture can enter freely.

5. Convenient thickness adjustment: The thickness of the honeycomb paperboard is adjusted by the thickness of the honeycomb core paper. The honeycomb paperboard structure always maintains a three-layer structure, and its thickness can be arbitrarily cut between 5-60mm; while the corrugated paperboard needs to increase the corrugated The number of layers or the thickness of the corrugated board is used to increase the thickness of the cardboard, and the amount of corrugated cardboard will be greatly increased, and the increase in the cost of honeycomb is limited.

6. Improved workshop utilization rate: the stacking height of corrugated cardboard cannot exceed 2 meters, while the stacking height of honeycomb cardboard is more than 8 meters, and it will not feed the bottom cardboard. The utilization rate of the honeycomb cardboard workshop is 4 times that of corrugated.

7. Reduced transportation costs: 1. Combining the advantages of point A, the same fully loaded honeycomb carton is 30%-40% lighter than corrugated boxes, and the fuel will be greatly reduced; 2. The frontal resistance of honeycomb cardboard The pressure is 5-10 times that of ordinary corrugated paper, and the flexural strength is 5-30 times that of corrugated paper. The inner lining material of the packaged goods can be reduced and thinned (Hisense and Haier have been streamlining their exports and domestic sales), so how can they be more packaged The transportation volume reduces the transportation cost for the user of the packing box.

8. Reduced stock of raw paper: Honeycomb paperboard can save 30%-40% compared with corrugated paperboard of the same thickness (combined with the advantage of point A), greatly reduce the stock of raw paper, thereby reducing the backlog of funds; corrugated board production office The specification of the base paper used is a change of 5cm, the specification of the base paper used in the production of honeycomb paperboard is a change of 20cm, and the specification of the corrugated base paper inventory is 4 times that of the honeycomb base paper.