The anti-theft door is not anti-theft, the honeycomb paper was wronged

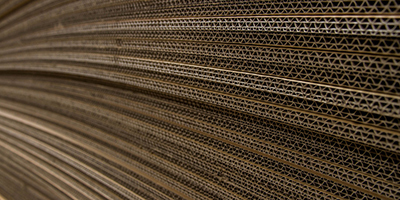

Since CCTV reported on the quality problems of anti-theft doors in its "Weekly Quality Report" on November 26, honeycomb paper has suddenly become the focus of various media attention and reports. The mainstream media in Guangdong has also set off various issues. Follow-up reports. For example, the headline of the Nanfang Daily report on the 27th was "Fake anti-theft doors are not made of cardboard and wood planks", the Guangzhou Daily report was "Inferior anti-theft doors were fake and not anti-thief", and the headline of the Southern Metropolis Daily was " Inferior security doors are broken in five minutes. The title of the new Express is "Shrinking Security Doors Hot in Guangzhou", and online media reports are overwhelming, portraying honeycomb paper as the culprit of unqualified security doors, as if using honeycomb paper The security door is a symbol of inferior products, honeycomb paper has become a scapegoat for inferior products and the object of various media condemnation. In fact, this is a complete misunderstanding of honeycomb structure materials, reflecting the ignorance and prejudice of some domestic media reporters on emerging industries and new materials, and an unfair treatment of the development of the honeycomb material industry. In such a humanistic environment, it is a kind of Emerging materials and an emerging high-tech new material industry may decline and die due to these one-sided reports and ignorant misunderstandings.

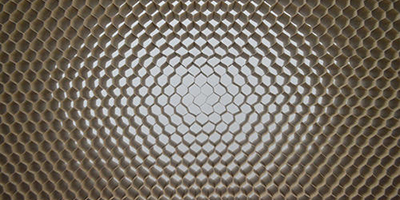

Honeycomb material is a kind of light-weight and high-strength structural material developed based on the principle of bionics and imitating the principle of bee building honeycomb. It has been mainly used for various structural components and internal structural panels of aviation and spacecraft. The main advantage of reducing the weight of the aircraft is its light weight and high strength. I believe many people have taken airplanes. If you know that the floor on airplanes is also made of a special honeycomb paper (aramid paper), would you doubt its quality and give up flying? my country's Shenzhou spacecraft also uses many honeycomb structure components. I believe no one doubts its reliability and quality. Everyone will understand that the quality of a product depends on its quality inspection standards. If the quality of a product meets the prescribed technical quality standards, the product is a qualified product, and it depends on the structure and materials used. Irrelevant.

On the other hand, the quality reports of domestic media on the anti-theft door, the problem is obvious, because the anti-theft door itself does not meet the relevant national standards of the "General Technical Requirements for Anti-theft Security Door", and does not meet the technical requirements and specifications of the anti-theft door regulations. The main reason is the adoption of It is caused by too thin steel plate. In fact, it has nothing to do with whether the honeycomb structure is adopted or not. The honeycomb paper is only an auxiliary filling material. If honeycomb paper is not used, the gap between the security door is either completely empty or filled with other materials. These materials themselves There is no anti-theft function, but only supports and reduces weight. In addition, the standard of my country's "General Technical Conditions for Anti-theft Security Doors" does not restrict the use of honeycomb paper as a filling material. Therefore, after the anti-theft door adopts a honeycomb structure, it can make The surface of the anti-theft door is flat and smooth, and the least material is used to occupy the largest space, which optimizes the structure of the anti-theft door and reduces the cost.

If we assume that the security doors are all made of steel plates, and the thickness of the security doors is generally about 40mm, such security doors certainly have the best anti-theft function. I believe it can not only prevent theft, but also bulletproof and explosion-proof, it is a real copper wall and iron wall. , But in real life, people simply cannot use such a security door, because its weight will be as high as 500 kilograms, not only can not be used normally, but also waste too much steel or other materials. What does our country rely on for advocating to build a resource-saving society? It relies on scientific principles, reasonable selection of materials and high-tech structure, and the honeycomb structure is a beautiful structure that nature gives mankind the most saving of materials.

The prejudice and lack of technical support reported by the Chinese media on honeycomb paper have not only put the manufacturers of paper honeycomb structure materials in trouble, but also made the development of a honeycomb material industry emerging in China even more difficult and difficult.

After World War II, paper honeycomb materials began to be used in European and American countries. At present, 80-90% of the doors used in Western countries use honeycomb paper as filling materials to reduce the use of wood and steel and maximize the material's efficiency. Utilization rate. In the past, honeycomb structure technology was a dual-use technology for military and civilian purposes, and the West restricted exports to my country. However, my country only began to develop and promote paper honeycomb material products in the early 1990s, and has made considerable progress and development in the past decade.

As early as the fourth century in ancient Greece, the mathematician Pappus believed that the beautiful shape of the honeycomb was the representative of the most effective work in nature, and that the hexagonal honeycomb of bees was the building structure with the least beeswax and the largest capacity. . Inspired by natural honeycombs, humans have studied and analyzed the characteristics of natural honeycomb structures for a long time, and creatively invented various honeycomb composite material structures and products. Some of them are used in the research and development of new materials and products, and some are used to improve existing ones. The characteristics of the product. In the field of applied materials, honeycomb composite materials are similar to continuous I-steel structures, and are well-known for their excellent compressive and flexural properties and ultra-light structural features. When compared with solid materials of the same type, the strength-to-weight ratio and rigidity-to-weight ratio of honeycomb materials are both the highest among known materials.

Honeycomb structure panels have many superior properties: from a mechanical point of view, compared with other structures, the closed hexagonal equilateral honeycomb structure can obtain the maximum force with the least material, and when the honeycomb structure panel is subjected to a load perpendicular to the board surface, Its bending stiffness is almost the same as or even higher than that of a solid sheet of the same material and thickness, but its weight is 70-90% lighter, and it is not easy to deform, crack and break, and has shock absorption, sound insulation, heat insulation and extremely strong The weather resistance and other advantages. The appearance of the processed honeycomb composite panel is the same as that of commonly used panels, but the quality is not reduced, but in many cases, it has been improved, such as bending strength, resistance to temperature changes, etc. Due to the special hexagonal structure of the honeycomb core, a large amount of material can be saved and the characteristics of the plate can be improved. The honeycomb composite panel has been widely used in aviation, aerospace and other high-tech fields, such as the fairing of launch vehicles, aviation and space shuttles. Structural components, etc.

In the civil field, the honeycomb structure material is generally made of 100% recycled paper, which can be made into various lightweight panels to replace solid wood panels, or made into lightweight wall panels and partitions for building materials and decorative panels. High-strength honeycomb paperboard can also replace EPS white foam materials for the packaging of home appliances, electromechanical and various industrial products. Structurally, any solid sheet can be replaced by honeycomb structure sheet, and the effective material used in honeycomb material is only 2-6% of the replaced material. For example, in the furniture manufacturing and packaging industry, 1,000 kg of paper Honeycomb materials can replace 30-50 cubic meters of solid wood panels, or 40-60 cubic meters of white EPS foam materials. Obviously, honeycomb materials are a kind of lightweight material with low material consumption and low energy consumption, which can not only save a lot of wood, etc. Natural resources can also greatly reduce the use of white foam that pollutes the environment.

We don't want to see that because of one-sided media reports and unanalyzed reasoning, honeycomb paper (honeycomb structure material) is portrayed as a low-quality product, and it becomes a scapegoat for some unscrupulous manufacturers. In the past ten years, we have been committed to promoting and developing my country's honeycomb material industry and have achieved extraordinary results. In the furniture industry, paper honeycomb structural panels are becoming the main substitute for solid wood panels, saving the country about 1 million cubic meters of wood each year, which is equivalent to protecting 15,000 hectares of forest resources each year. In the packaging field, all-paper honeycomb materials are gradually replacing wood packaging materials and EPS white foam packaging materials, which can reduce the use of about 1.5 million cubic meters of white foam each year, which not only saves a lot of wood resources for the country, but also effectively reduces whiteness. The use of foam reduces environmental pollution, thereby protecting our deteriorating natural environment and ecology. We firmly believe that honeycomb materials will make an indelible contribution to the construction of a resource-saving and environment-friendly society in our country. We also hope that our media will provide fairness and accuracy to the development of my country's honeycomb material industry with a scientific attitude and realistic style. Reports.